3 min read

The Benefits of Offline Filtration

By Hy-Pro Marketing on Wed, Apr. 25, 2018

Topics: offline filtration

6 min read

What to Look for in a Dissolved Metal Analysis

By Jennifer Yeadon on Thu, Mar. 08, 2018

Oil can be high maintenance. It’s not something you just dump in your system and forget about. You have to monitor it, manage it and oversee it. Just letting oil cycle through your system without routinely testing it is a sure ticket to equipment damage.

Topics: contamination oil analysis metal analysis

3 min read

Breathers: An Essential Part of Total System Cleanliness

By Hy-Pro Marketing on Wed, Feb. 21, 2018

Controlling the contaminant flow of your hydraulic, lubricant or fuel reservoirs is one of the simplest goals in achieving Total Systems Cleanliness.

Topics: contamination total systems cleanliness breathers

4 min read

Parsing Filter Media and Filter Element Types

By Hy-Pro Marketing on Thu, Feb. 01, 2018

In the fascinating and fundamental field that is industrial fluid filtration, there exist many types of filter elements and many different types of media. In this article, we will briefly cover filter elements and the most common types of media they're made up of. The medias featured below include: cellulose, glass, wire mesh and water removal, coalesce and resin.

Topics: contamination filtration filter elements

3 min read

DFE: Testing Filters Under Real-Life Conditions (Part 4 of 4)

By Hy-Pro Marketing on Tue, Jul. 18, 2017

Throughout the first three entries in this series (find parts one, two and three), we've discussed the difference in two filter element testing methods, ISO16889 and DFE. We've also illustrated how many elements fall short of their stated beta ratio under dynamic flow conditions. Today we'll wrap it up with simulated cold-start tests.

DFE Multi-Pass: Cold Start Contamination Retention

Once the element has captured enough contaminant to reach approximately 90% of the terminal ΔP (dirty filter indicator setting), the main flow goes to zero and the injection system is turned off for a short dwell period. Then the main flow goes to maximum element rated flow accompanied by real-time particle count to measure retention efficiency of the contaminant loaded element. The dynamic duty cycle is repeated to further monitor the retention efficiency of the filter element after a restart.

Topics: ISO 16889 case study filter performance filter elements

4 min read

DFE: Testing Filters Under Real-Life Conditions (Part 3 of 4)

By Hy-Pro Marketing on Tue, Jul. 11, 2017

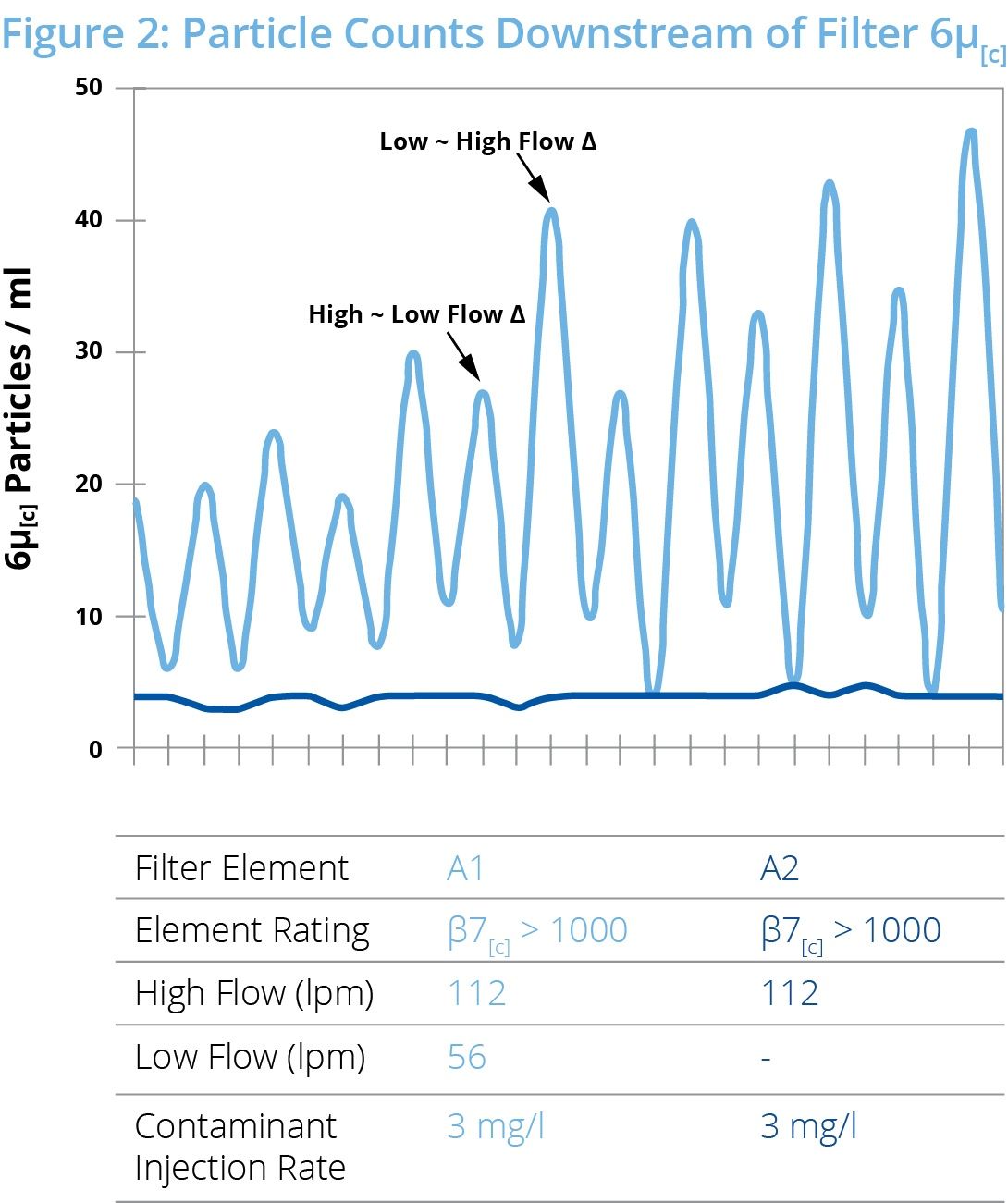

Last week we covered the differences between the ISO16889 Filter Test Procedure and the DFE Filter Test Procedure. This week we illustrate the difference between elements engineered to retain particles during dynamic flow conditions and those that are engineered only to pass the ISO16889 test. (Looking for previous posts? Find parts one, two and four.)

Topics: ISO 16889 case study filter performance filter elements

2 min read

DFE: Testing Filters Under Real-Life Conditions (Part 2 of 4)

By Hy-Pro Marketing on Tue, Jun. 27, 2017

Last week, in part one, we briefly discussed how filter elements are rated by manufacturers. This week we're discussing the industry standard ISO16889 multi-pass test and Hy-Pro's standard, the DFE test. (Already read part two? Read parts three and four.)

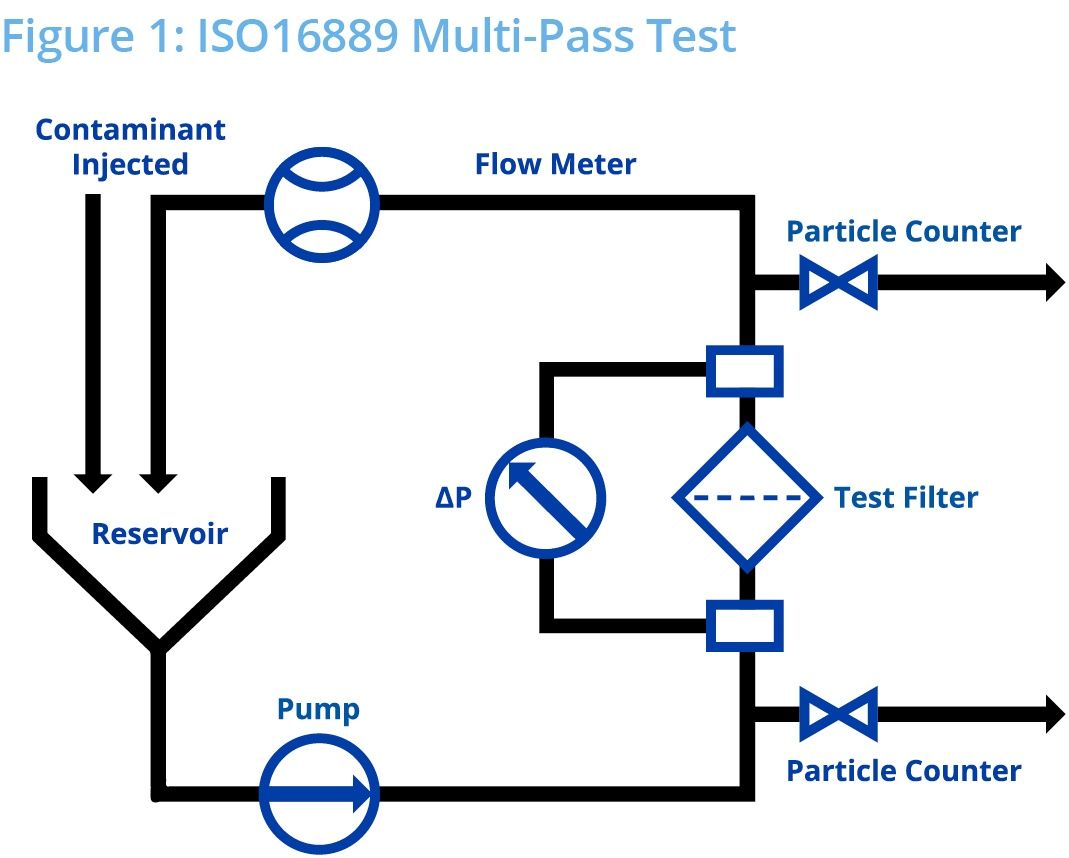

Current Filter Performance Testing Methods

To understand the need for DFE, it is important to understand how filters are currently tested and validated. Manufacturers use the industry standard ISO16889 multi-pass test to rate filter efficiency and dirt-holding capacity of filter elements under ideal lab conditions.

Figure 1 depicts the test circuit where hydraulic fluid is circulated at a constant flow rate in a closed-loop system with on-line particle counters before and after the test filter. Contaminated fluid is added to the system at a constant rate. Small amounts of fluid are removed before and after the

Topics: ISO 16889 case study filter performance filter elements

3 min read

DFE: Testing Filters Under Real-Life Conditions (Part 1 of 4)

By Hy-Pro Marketing on Tue, Jun. 20, 2017

The Dynamic Filtration Efficiency (DFE) Test is Hy-Pro's standard for testing filter elements. Throughout this four-part

First, let's start with the basics.

Why are filters used? How are they rated?

All hydraulic and lube systems have a critical contamination tolerance level that is often defined by -- but not limited to -- the most sensitive system component such as servo valves or high-speed journal bearings. Defining the ISO fluid cleanliness code upper limit is a function of component sensitivity, safety, system criticality and ultimately getting the most out of hydraulic and lube assets.

Topics: ISO 16889 case study filter performance filter elements

3 min read

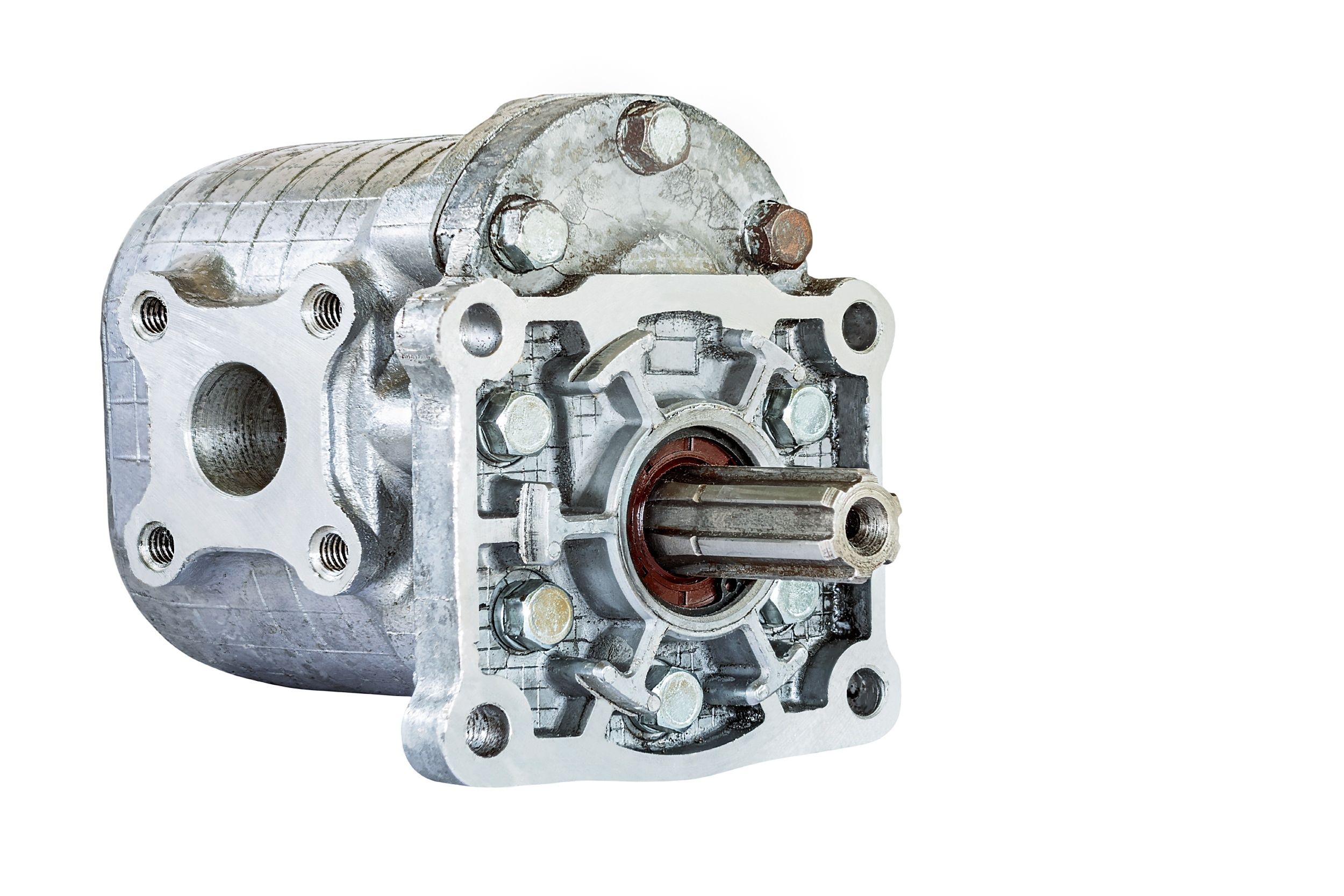

When a Pump Fails, the Whole System Fails: Hydraulic Pump Reliability

By Hy-Pro Marketing on Tue, Feb. 21, 2017

The Problem: Hydraulic Pump Failure

Pumps are the heart of hydraulic systems. When the pump fails, the entire system is down until the pump is operational again. This poses a serious threat to any operation relying on hydraulic systems for productivity.

Recently, a hydraulic valve manufacturer was losing 25 pumps a year on their centralized hydraulic system at a cost of $2,440 each -- and that’s only the pump cost. When you account for maintenance resources, lost oil and lost production, each failure costs ~$25,320.

Topics: hydraulic fluid ISO 4406 breathers case study hydraulic pump

2 min read

Hydraulic Valve Performance Test Stands and Clean Oil

By Hy-Pro Marketing on Tue, Nov. 29, 2016

The Application

A hydraulic valve manufacturer required pristine fluid (< 14/12/9) to test flow across an 80-micron orifice on their test stand. Gross amounts of contamination in the fluid would skew the test results, invalidating any data collected.

The system held 100 l (26.4