Choosing the best filter element size and media for a specific application can be tricky. You want media that is tight enough to help you reach your target ISO code. However, if you choose a media that is too tight for your application, the element differential pressure (Delta P or ΔP) will rise too quickly and you will be replacing elements far too frequently.

Choosing the best filter element size and media for a specific application can be tricky. You want media that is tight enough to help you reach your target ISO code. However, if you choose a media that is too tight for your application, the element differential pressure (Delta P or ΔP) will rise too quickly and you will be replacing elements far too frequently.

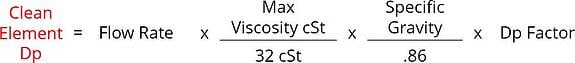

To prevent these situations you should always calculate clean element Delta P whenever changing the filter media or manufacturer.

Step 1: Gather Necessary Information

Before you start, you'll need to gather a few pieces of essential information. They are:

-

Flow rate

-

Lowest temperature

What is the lowest temperature this oil will reach during shutdown, transfer, etc? (This will be used to calculate maximum viscosity in centistokes.) -

Specific gravity of the fluid

-

Filter element ΔP factor

Step 2: Viscosity Chart Calculations

Use a viscosity chart to calculate the maximum viscosity of the fluid at its lowest temperature in centistokes.

Step 3: Calculate the Delta P

Use the information you have gathered to solve the equation below for clean element Dp.

And that should be it for calculating your clean element Delta P. If you have any questions, please let us know if the comments below.