Glass or Cellulose: Which Hydraulic Filter Media is Best?

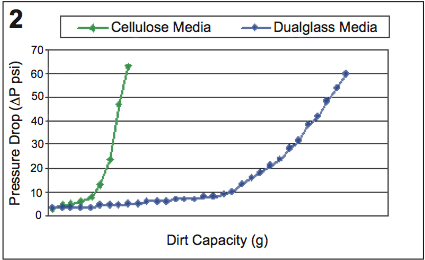

There are several distinct differences between glass and cellulose media. Media selection should be based on the required cleanliness and other unique needs of the system. Evaluate the Beta ratio (efficiency), dirt holding capacity, flow versus pressure drop characteristics, etc. A hydraulic filter supplier should be able to supply more detailed test information in addition to what is supplied in the literature.

Cellulose vs. Glass: Absolute and Nominal Filter Efficiency

Normally, wire mesh and cellulose media elements are nominally rated, which means they might be only 50% efficient at the rated micron size. Most glass media elements are considered to be “absolute” rated which means that they are 99.5% efficient at the rated micron size. Check the Beta ratio before selecting the media as all “

Elements of different media with the same “micron rating” can have substantially different filtration efficiency. The graphic below provides a visual representation of the difference between absolute and nominal filter efficiency.

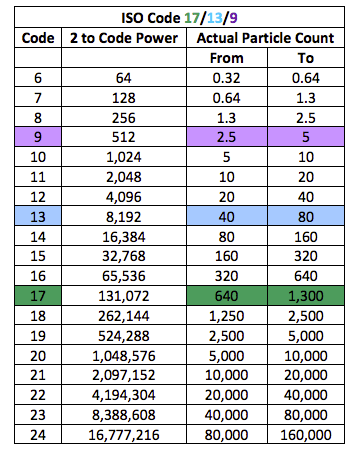

The illustrated glass element would typically deliver an ISO Fluid Cleanliness Code of 18/15/8 to 15/13/9 or better depending upon the system conditions and ingression rate. The cellulose element would typically achieve a code no better than 22/20/17.

Cellulose vs. Glass: Fibers and Cleaning

Runaway contamination levels at 4μ[c] and 6μ[c] are very common when cellulose media is applied where a high population of fine particles exponentially generate more particles in a chain reaction of internally generated contaminate.

Inorganic glass fibers are much more uniform in diameter and are smaller than cellulose fibers. Organic cellulose fibers can be unpredictable in size and effective useful life. Smaller fiber size means more fibers and more void volume space to capture and retain contaminate.

The majority of hydraulic filter elements today are designed to be disposable and utilize media constructed of synthetic or organic fibers. These elements are non-cleanable and must be disposed of after their useful life. Some applications are fitted with stainless steel wire mesh media elements that yield a very

It is important to note that the cleaning process may be destructive, which can compromise the element’s efficiency and integrity (ultrasonic cleaning, high-pressure steam cleaning). Cleanable elements typically have a shorter life than their disposable counterparts made of glass or cellulose media, size for size. Wire mesh media elements are typically applied to systems with high viscosity fluids that do not require ultra clean fluid (gearbox pressure line in

Best Hydraulic Filter Media: Glass

Absolute rated high-efficiency glass media elements are the most suitable selection for achieving target ISO cleanliness codes on systems with components that are sensitive to contamination (servo valves, piston pumps, etc). Consult component manufacturers for required fluid cleanliness as this can be directly correlated to warranty requirements. Filter suppliers can also be a valuable resource for determining overall system cleanliness guidelines.

When upgrading to an absolute efficiency glass media element the system cleanliness must be stabilized. During this clean-up period, the glass element halts the runaway contamination as the ISO cleanliness codes are brought into the target cleanliness range. As the glass element removes years of accumulated fine particles, the element life might be temporarily short.

Once the system is clean, the glass element can last up to 4-5 times longer than the cellulose element that was upgraded.