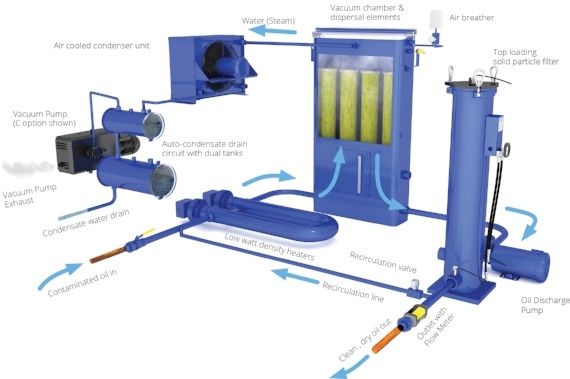

Hy-Pro Vacuum Dehydrators Improve Mill Reliability

We Hy-Pro Vacuum Dehydrators already know that maintaining low levels of water in rolling mill lubricating oil can help improve uptime, extend oil life, prevent bearing failures and increase profitability. But, what about an actual example of how a vacuum dehydrator has improved mill reliability?

Real-World Problem: Mill Decants Emulsified Water Every Shift

A Hy-Pro Vacuum Dehydrator was installed on an 8000-gallon rolling-mill lube reservoir that was plagued by high amounts of water in the lube oil. There were immediate results: the vacuum reduced water levels from 2.9% (29,000 ppm) to 1.7735% (17,735 ppm) in the first day. After two weeks, the water level in the entire system has stabilized at .0383% (383 ppm). Since installing a vacuum dehydration system and reducing the level of water in the system, the mill hasn’t had a bearing failure.

Before the vacuum

Hy-Pro Vacuum Dehydrator and Improved Oil Cleanliness

Hy-Pro Vacuum Dehydrators are designed to operate unattended and have automatic water drainage and oversized particulate hydraulic filter elements. You will see improved oil cleanliness and you will be able to remove all forms of water in the oil. You don’t have to worry about free, emulsified or dissolved water in your oil any longer. The Hy-Pro VUD does not require the frequent maintenance attention that centrifuges need, which will ease the burden of personnel.

By using a vacuum dehydrator system, you can remove water from your oil, extend the oil’s useful life and save bearings. By doing all of this, a vacuum dehydrator can save you money and increase your profitability.