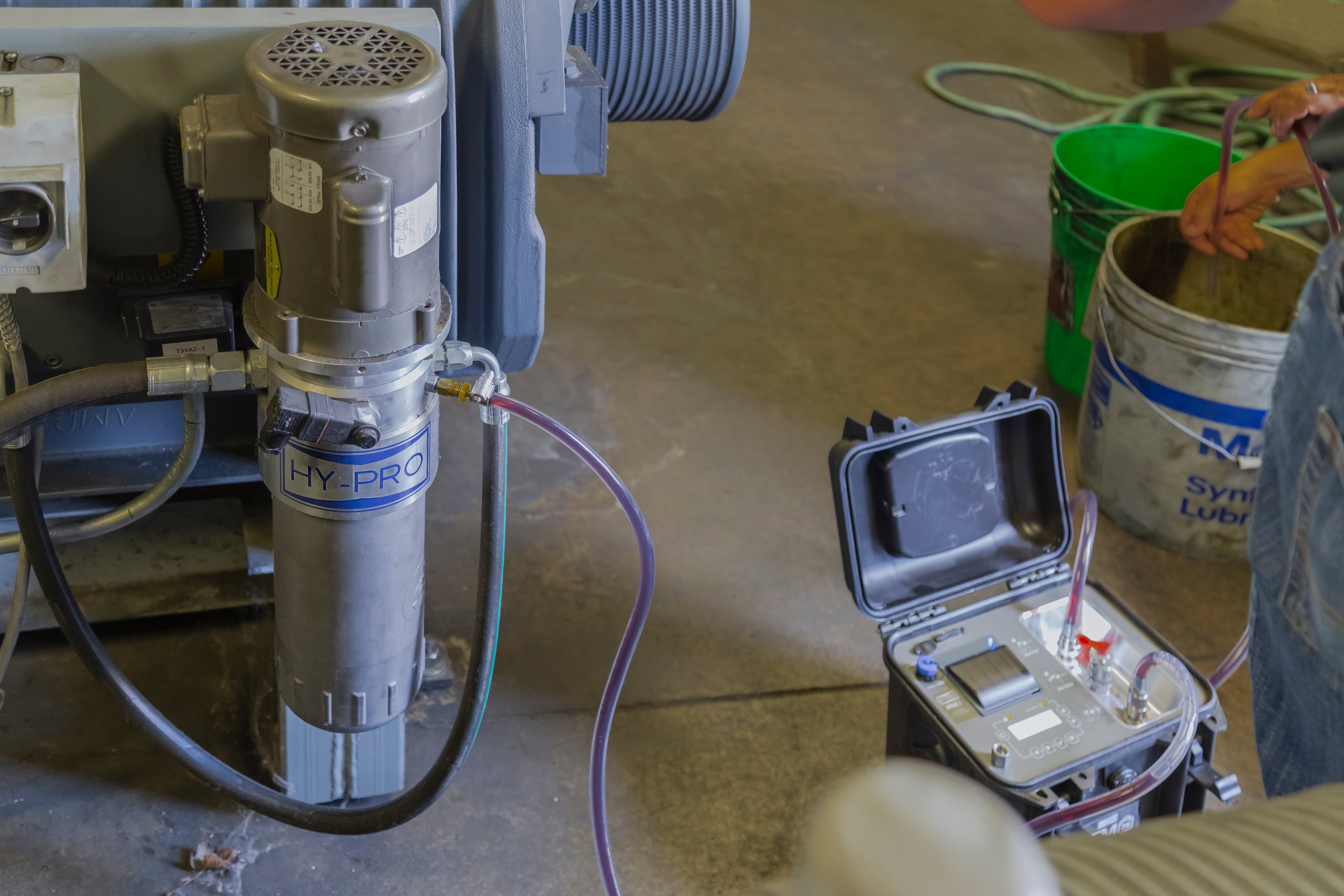

Our smallest unit yet, the Compact Offline Filter is able to fit where no other filtration equipment can. Ideal for smaller systems, or where a larger offline system wouldn't fit, can be permanently installed or portable.

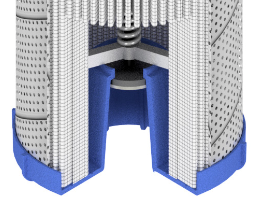

Typical applications include gear boxes, plastic injection molding machines, and vacuum pumps, to name a few. Choose between a variety of motors, wands, hoses, and portable cart options. Paired with our unique VTM elements, this unit can remove particulate, water, and varnish all with one filter.