Quantifying Contaminant Capture and Retention

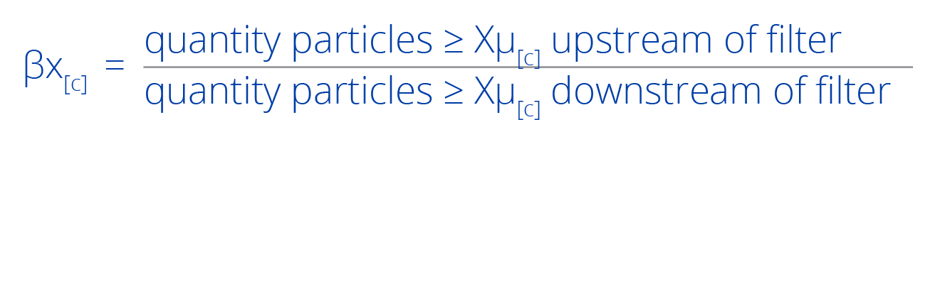

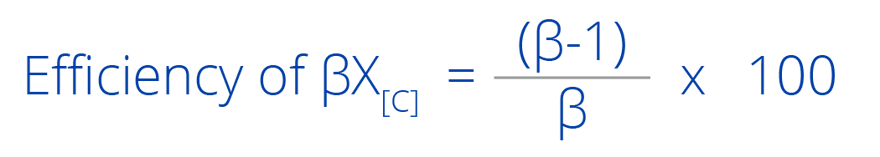

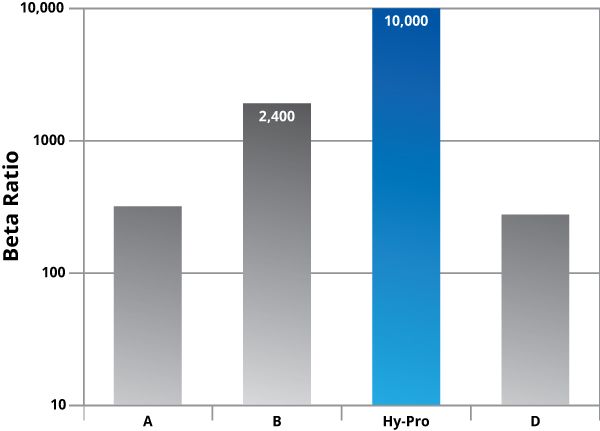

Filters for critical hydraulic, lube, and fuel systems are specifically designed for high-efficiency particle capture. However, a filter is not a black hole, capturing and retaining particles in a real-world dynamic environment is far more challenging. Hy-Pro pioneered the DFE (Dynamic Filter Efficiency) multipass test to optimize performance under real-world conditions. This methodology drives the development of proprietary media layers, media support structure, and filter construction. The results are higher efficiency particle capture and retention and cleaner fluids when Hy-Pro upgrade elements are in service.

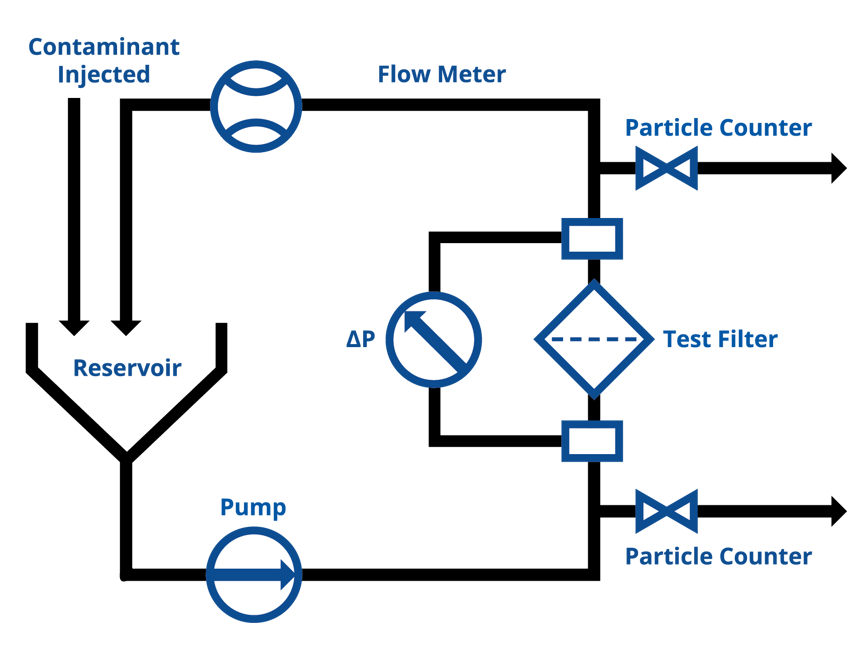

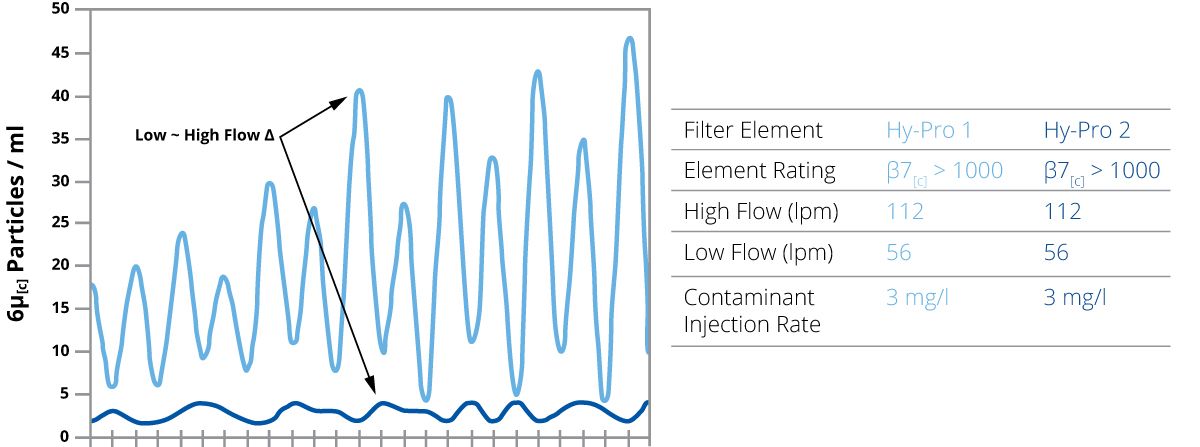

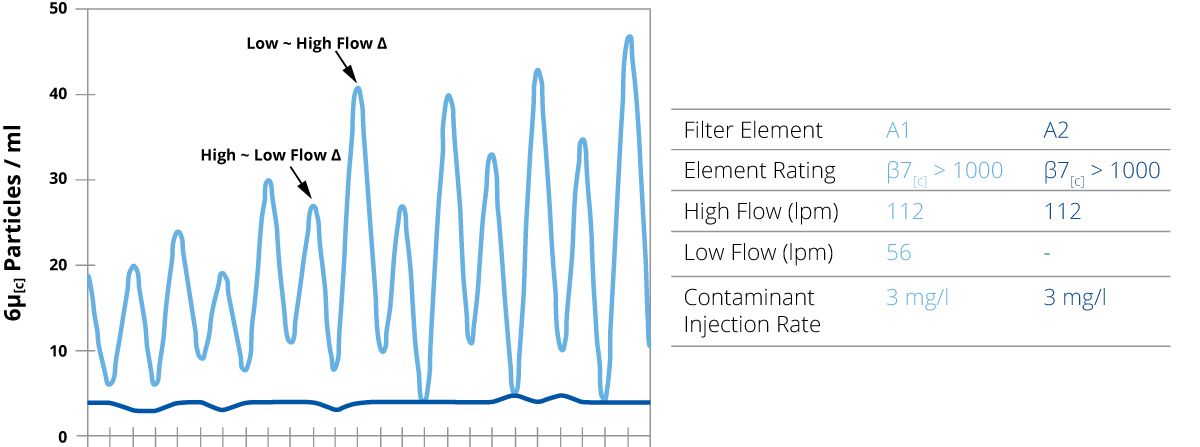

Hy-Pro uses DFE and the ISO/CD23369 Cyclic Flow Multi-Pass Test to benchmark performance between its filters and those of its competitors. The Cyclic Flow Multi-Pass protocol ISO/CD23369 moves the industry-standard one step closer to real-world conditions by incorporating cyclic flow with rapid flow transitions (between 100-200 msec) as shown in Figure 2.

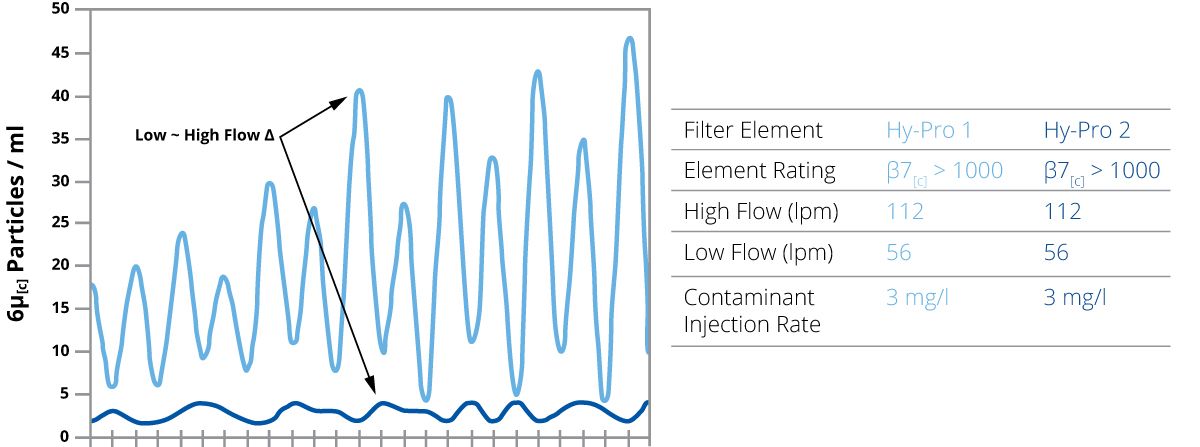

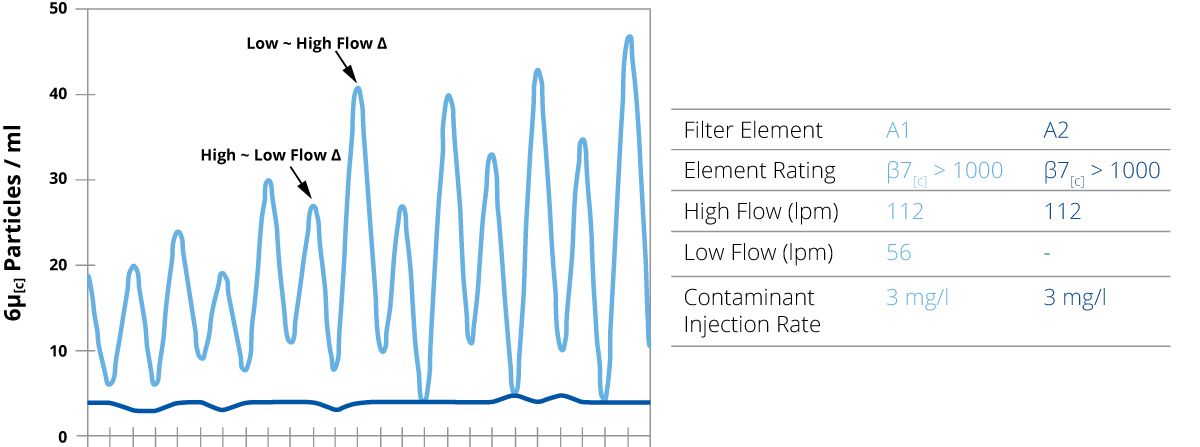

Figure 2: Particle Counts Downstream of Filter 6µ[c]

- Figure 2 compares the performance of two identical high efficiency glass media filter elements, one tested to ISO16889 multi-pass and the other to the DFE multi-pass method. The graph expresses the actual number of particles 6μ[c] and larger counted downstream of the filter element from several data points during the tests.

Filter A2 was tested at a constant flow rate and maintained a steady efficiency throughout the test. Filter A1 was cycled between max rated flow rate and half of rated flow with a duty cycle consistent with that of a hydraulic system. The downstream counts for Filter A1 varied and were highest during changes from low flow to high flow. The peaks represent counts taken during flow change and the valleys represent counts taken after each flow change. The alternating high peaks represent counts taken during changes from low flow to high flow. As the amount of contaminant captured by Filter A1 increased, the downstream counts increased most dramatically during the flow changes from low to high. Filter element A1, not properly designed to retain previously captured contaminant during dynamic system conditions, can become a dangerous source of contamination as it captures and then releases concentrated clouds of contaminated fluid.

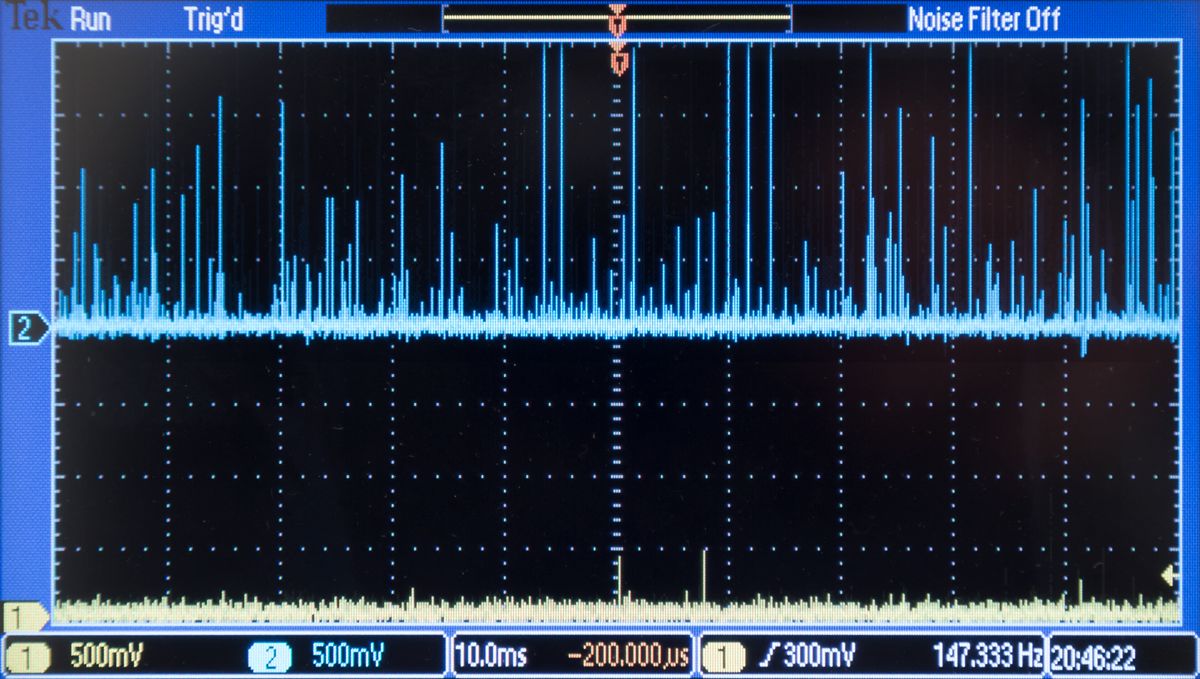

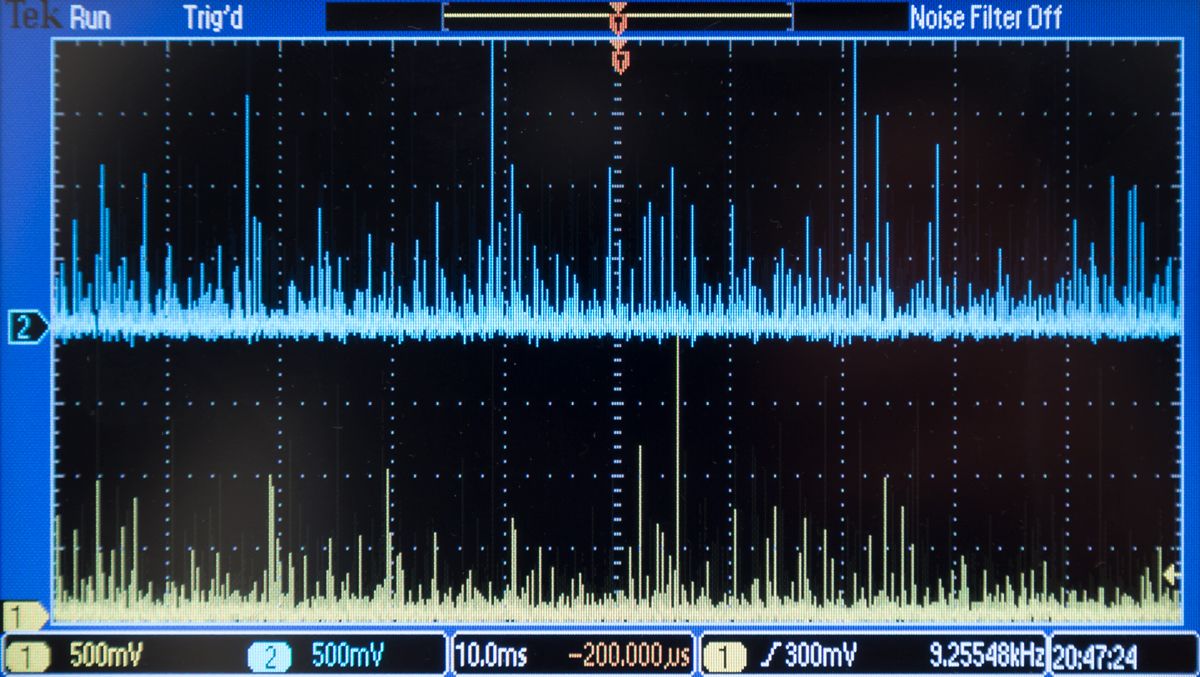

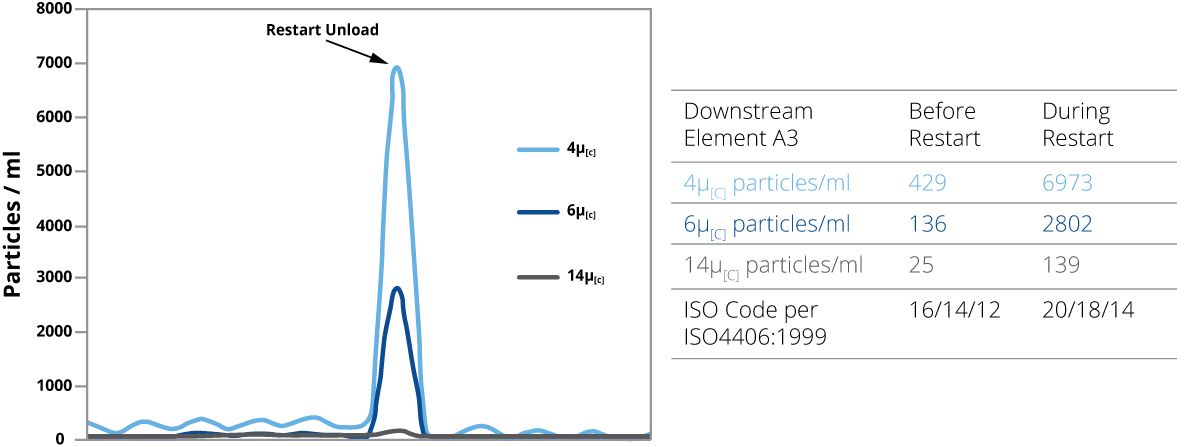

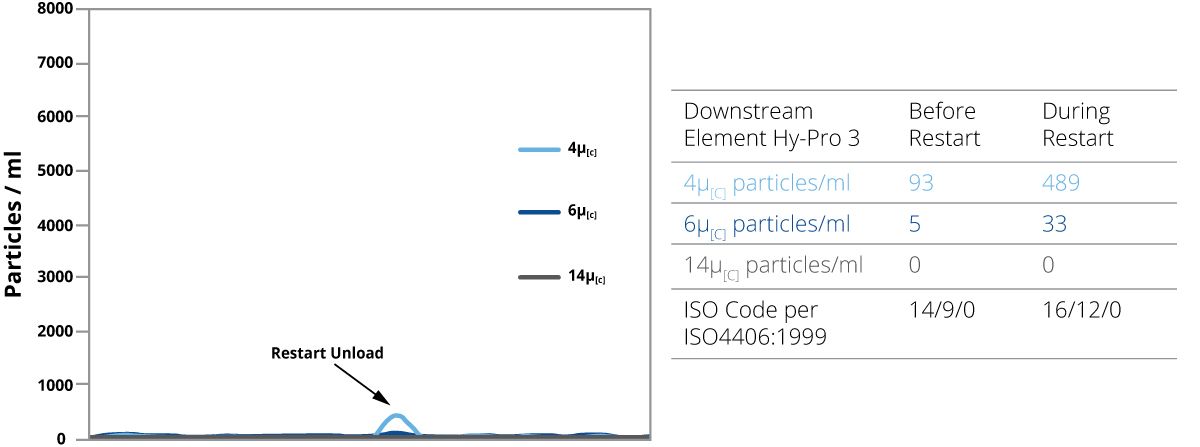

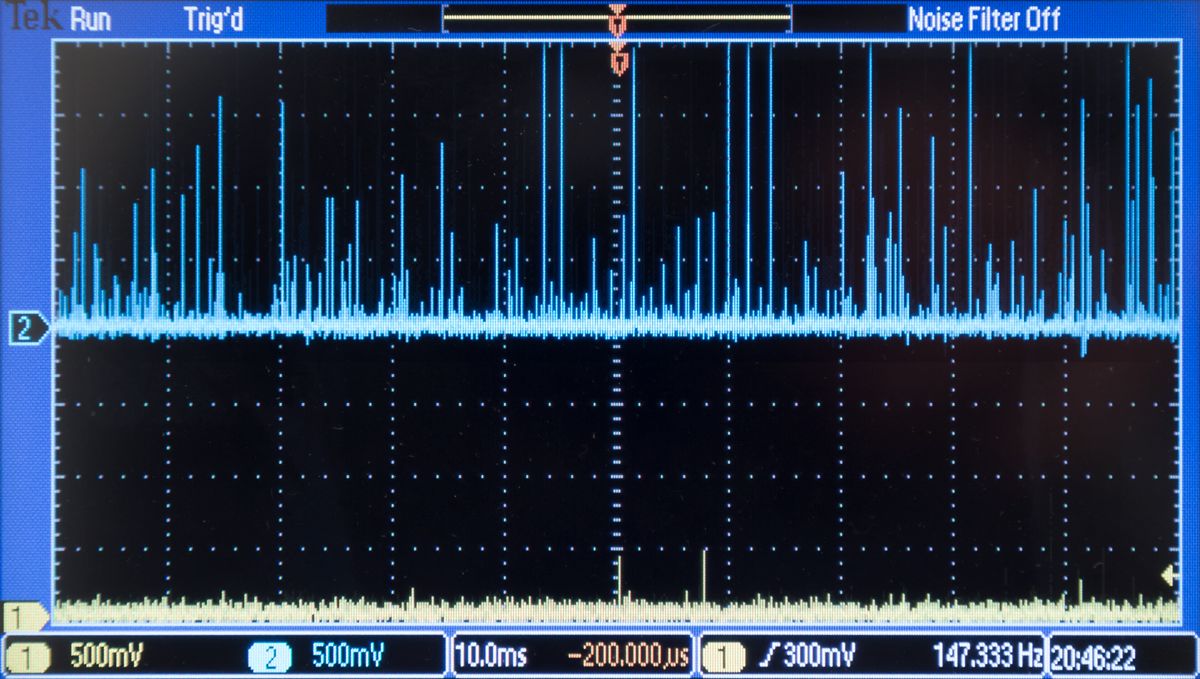

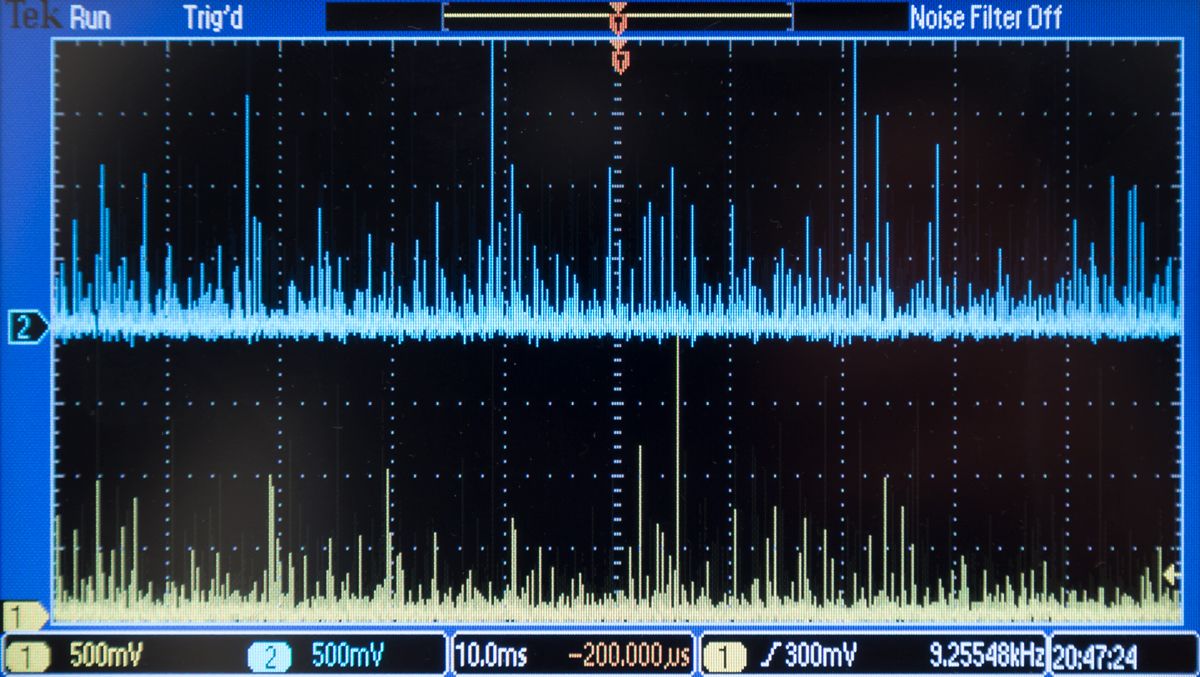

Figure 3 shows the particle counter raw data (top- upstream, bottom-downstream) for Element A1 before a change from low flow to high flow and Figure 4 shows the particle counter data for Element A1 during a change from low flow to high flow. The downstream particle count trace during the change reveals a much higher quantity of smaller particles and larger particles that did not pass the element before the dynamic system condition. This phenomenon can best be described as “contaminant unloading”. As the filter element captures more dirt, greater amounts may be released back into the system that it is installed to protect when the element is subjected to a dynamic flow condition and change in differential pressure across the element. Unloading may also occur when the flow rate changes from high flow to low flow, represented by the alternating smaller peaks in Figure 3. The filter element typically recovers shortly after the dynamic condition, but highly contaminated clouds of fluid from contaminant unloading can cause severe component damage and unreliable system performance. -

Figure 3: Element A1 Before Flow Change

Figure 4 : Element A1 During Flow Change

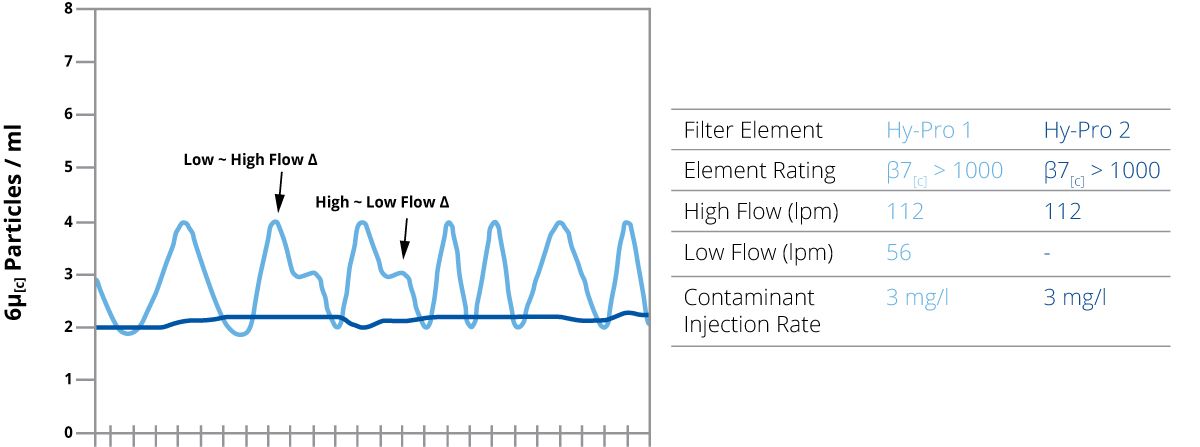

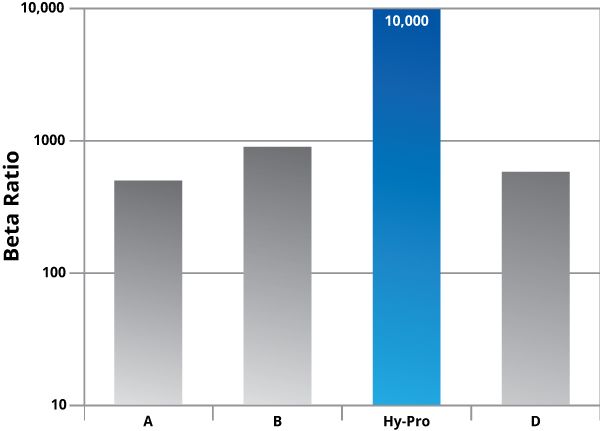

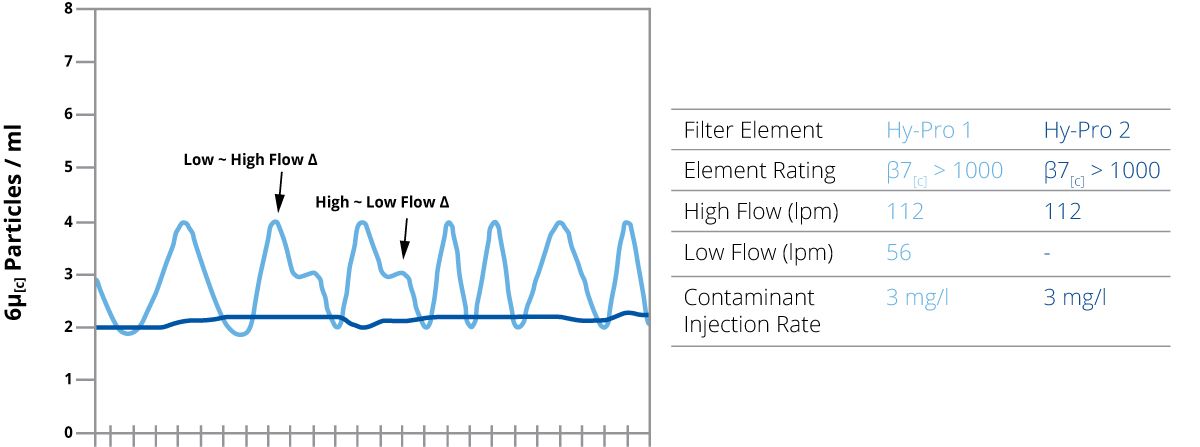

Figure 5 compares the performance of two identical Hy-Pro filter elements designed and developed per the DFE multi-pass test method. All Hy-Pro elements that utilize the G8 or higher media carry the Hy-Pro DFE rating.

Although the contaminant unloading effect is still evident, the unloading is insignificant as filter element Hy-Pro 1, tested per DFE, performed true to its ISO16889 multi-pass rating of β7[c] > 1000 even during dynamic flow conditions.

Figure 5: Particle Counts Downstream of Filter 6µ[c]

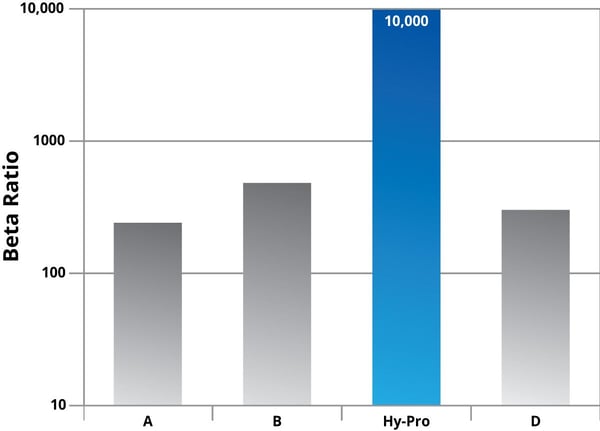

Figure 6 compares the performance of filter Element A1 and Hy-Pro 1 (DFE rated). Both elements demonstrated excellent particle capture performance during the ISO16889 and DFE testing. The DFE rated Hy-Pro element yielded much more stable particle counts downstream of the element and more consistent efficiency during the dynamic flow conditions. Improving particle retention results in more predictable fluid cleanliness levels and a system that can continually operate below the ISO cleanliness code limit.

Figure 6: Particle Counts Downstream of Filter 6µ[c]