Despite thousands of dollars and hours spent trying to mitigate the effects of varnish in turbine oil, many still suffer from this ongoing yet solvable issue. When combustion and steam turbines fall victim to unit trip or fail-to-start conditions, varnish is the usual suspect.

3 min read

Varnish in Turbine Oil Systems

By Aaron Hoeg on Wed, Oct. 06, 2021

Topics: water Water Contamination varnish SVR contaminination turbine oil

1 min read

Hy-Pro's Product Spotlight: Compact Offline Filter (COF)

By Brad Bainbridge on Thu, Apr. 01, 2021

Hy-Pro's Compact Offline Filter

Our newest and smallest unit yet, the Compact Offline Filter is able to fit where no other filtration equipment can. Ideal for smaller systems or where a larger offline system wouldn't fit, this solution can be permanently installed or made portable for ease of use.

to fit where no other filtration equipment can. Ideal for smaller systems or where a larger offline system wouldn't fit, this solution can be permanently installed or made portable for ease of use.

Topics: hydraulic fluid contamination dirt Water Contamination hydraulic filters hydraulic and lubrication filter types Gearbox filtration new oil micro-dieseling fluid samples filtration oil analysis hydraulic pump filters hydraulic valve FSL liquid conditioning station duplex low-pressure oxidation Noria NSD hydraulic cellulose media compressor Reliable Plant filter comparison lube oil aluminum refinery conditioning turbine oil glass media

4 min read

Diesel Fuel Filtration 101

By Brad Bainbridge on Wed, Apr. 02, 2014

Reduce unplanned downtime and maximize the fuel efficiency of your diesel engines

Diesel engines are widely used today. You can find them inside buses and tractor trailers traveling our roads, humming along in construction equipment and drill rigs, submerged in marine environments and helping save lives in hospital generators, amongst many other applications. Diesel engines are popular for good reason. Not only do they have cleaner exhaust emissions, they are also known for more reliable starts

Topics: water Water Contamination diesel filtration case study contaminination

6 min read

Real Solutions to Bringing Phosphate Ester Under Control

By Scott Howard on Mon, Oct. 14, 2013

If controlling phosphate ester seems about as elusive as lassoing a bucking bronco, then you've come to the right place. Put on your cowboy hat and let's talk about real solutions to getting it under control.

Topics: water Water Contamination Phosphate Ester EHC contaminination acid

4 min read

What is a Vacuum Dehydrator?

By Scott Howard on Mon, Sep. 30, 2013

If the hydraulic, lubricating, compressor or gear oil you use is not made of a water base in

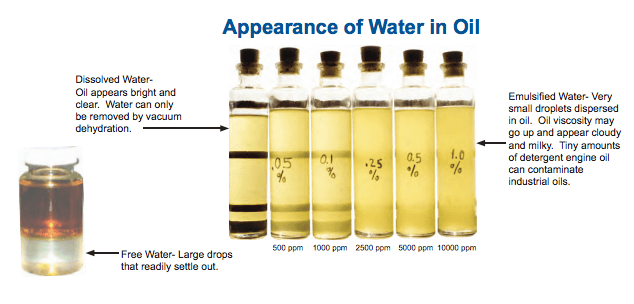

There are three types of water in a typical system: free water

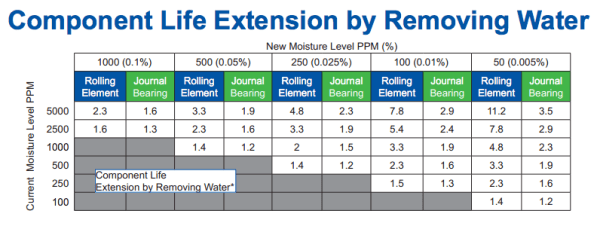

Using 100ppm for an upper water limit for most systems using mineral base oils, this means all free and emulsified water and a significant portion of dissolved water must be removed.

A vacuum dehydrator is one of the very few methods to remove dissolved water from oil. Let's take a look at these three types of water in your system. It will give you a solid foundation for how the vacuum dehydrator works in the end.

Topics: water Water Contamination vacuum dehydrator contaminination VUD

2 min read

Hydraulic Oil Water Removal

By Aaron Hoeg on Wed, Nov. 14, 2012

Water, it's a compound that is required for practically everything on the earth. But within a lubrication or hydraulic system, it's one of the most damaging contaminants possible. Unfortunately, it's also one of the most common contaminants you'll find in your system.

When your lubrication or hydraulic system is continuously or even periodically exposed to high water levels, it can result in a mountain of damage. You can find evidence of water contaminant destruction if you look close enough. This damage appears

Topics: water Water Contamination SVR hydraulic oil contaminination

2 min read

Oil Vacuum Dehydrators: Managing Water in Rolling Mill Lubricating Oil

By Aaron Hoeg on Fri, Aug. 31, 2012

In our last post, Improving Rolling Mill Oil with Vacuum Dehydration, we discussed how the