2 min read

Expanding the distribution of our Podcast; Apple Podcasts, Spotify, and PodBean

By Hy-Pro Marketing on Tue, Oct. 12, 2021

Topics: iso cleanliness codes DFE contaminination Podcast ISO 23369 Factoryside Chat Podcast

4 min read

[Video] How Big is a Micron?

By Hy-Pro Marketing on Mon, Aug. 26, 2013

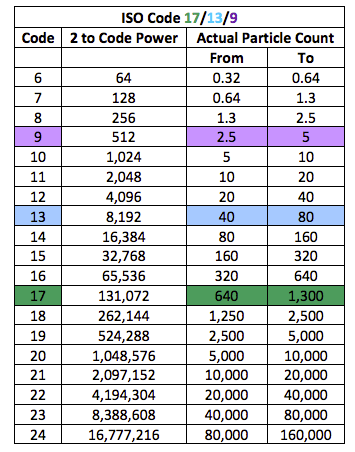

If you’ve been following our blog, you probably have a pretty solid understanding of ISO fluid cleanliness codes (if not, click here). You know that ISO codes quantify levels of particulate contamination at three different micron sizes (4μm/6μm/14μm), but how big is a 4μm particle? Watch the video below for a brief explanation of micron size.

Topics: iso cleanliness codes video

2 min read

Getting Started with Selecting Target ISO Cleanliness Codes

By Hy-Pro Marketing on Mon, Jul. 29, 2013

Here at Hy-Pro, we understand the importance of selecting target ISO Cleanliness Codes. That’s why we’ve put together this set of instructions for selecting target codes in case you’re in need of a little help.

Topics: iso cleanliness codes

1 min read

Improving Rolling Mill Lube Oil Performance and Useful Life - Part 3: Solution

By Hy-Pro Marketing on Mon, Mar. 18, 2013

At the end of Part 2, we discussed the winning nature of vacuum dehydration. If you missed Part 1 in the series, you can find it here.

At the end of Part 2, we discussed the winning nature of vacuum dehydration. If you missed Part 1 in the series, you can find it here.

Did you know that hydrogen is the friendliest molecule - meaning that it is most likely seeking partners to attach to? Similarly, the suspended particles in oil actively look for particles to join forces, so they pair with the water.

This particulate contamination is the catalyst guilty of continuing the degradation of the oil and the increase of emulsified water. The more water there is, the more oxidation that occurrs. This also increases various acids that form as the molecules break down. These acids attack seals, hoses, pumps and metal.

Topics: contamination iso cleanliness codes steel mills rolling mill lubricating oil vacuum dehydrator

2 min read

Improving Rolling Mill Lube Oil Performance and Useful Life - Part 2: Prevention

By Hy-Pro Marketing on Fri, Feb. 22, 2013

If you're just tuning in and didn't catch the first part of our steel mill and lube oil series, click here.

When we left off, we just determined how the high levels of emulsified water and high particulate contamination levels work together to cause bearing failure and reduce oil life. So, how do we prevent this expensive combination from happening? We're glad you asked!

Topics: contamination iso cleanliness codes steel mills rolling mill lubricating oil oil mills vacuum dehydrator

2 min read

Improving Rolling Mill Lube Oil Performance and Useful Life - Part 1: Quality

By Hy-Pro Marketing on Fri, Feb. 15, 2013

Premium oils keep steel mills running. It's crucial to protect their quality in order to keep the mills fully functioning.

In both hot and cold steel mill production, high-demulsibility lubricant is used for backup roller bearing lubrication. Some of these oils are referred to as SD, which stands for super-demulsibility. Not surprisingly, these SD oils are a premium product and come at a premium price. If a manufacturer wants to invest in these big-ticket oils, they obviously want to go to great lengths in order to keep them clean and fully functioning.

Join us for this three-part series as we take an in-depth look at improving rolling mill lube oil performance and useful life.

Topics: contamination iso cleanliness codes steel mills vacuum dehydrator

4 min read

[Video] Decoding ISO Fluid Cleanliness Codes

By Hy-Pro Marketing on Thu, Jan. 10, 2013

You likely know that there's a direct link between fluid cleanliness and component life-span. But when it comes to ISO cleanliness codes, does it all look like gibberish to you? If you answered "yes," then we can help. Watch the video below for a great primer on ISO Fluid Cleanliness Codes. You can also find the transcript below the video.

Topics: iso cleanliness codes video

8 min read

ISO 4406: What Do Those Numbers Mean in the ISO Cleanliness Codes?

By Hy-Pro Marketing on Mon, Oct. 08, 2012

Guest post today by Dan Helgerson. He is the Technical Editor of the Fluid Power Journal, where this article was originally published.

We have been talking a lot about filtration here at the steel mill. My predecessor had done a remarkable job in educating by example, demonstrating the need for good control of the fluids in our hydraulic and lubrication systems. He had helped stop the leaks and had added well-thought-out filtration systems that have resulted in substantial savings and increased productivity.

There is still a lot of work to be done and in pursuing that we have invited a number of vendors in, each offering an approach to getting and maintaining an acceptable fluid cleanliness level. The one thing that they all have brought to the table is a discussion of the ISO Cleanliness code. I was in a meeting with a group of managers when one vendor began to talk about the code. Being a Certified Fluid Power Accredited Instructor (AI), I immediately saw this as an obvious teaching moment, so I asked, “Does anyone here want to know what those numbers mean?” The answer was a quick and resounding, “No!”