In industrial operations, the efficiency and reliability of your industrial hydraulic systems are paramount. These systems are the muscle behind much of your heavy machinery, and even minor contamination or neglect can lead to costly downtime and premature equipment failure. That's where Donaldson’s professional, specialized service becomes invaluable.

4 min read

Essential Hydraulics Services from Donaldson

By Donaldson Hy-Pro Marketing on Thu, Dec. 11, 2025

Topics: contamination new oil fluid samples samples cleanoil oil handling best practices hydraulic oil cleanliness

9 min read

Understanding ISO 4406 Cleanliness Codes: A Complete Guide to Fluid Contamination and Reliability

By Donaldson Hy-Pro Marketing on Wed, Dec. 03, 2025

Topics: contamination fluid cleanliness ISO Fluid Cleanliness Codes filter elements cleanoil hydraulic oil cleanliness hydraulic oil maintenance lubrication systems

2 min read

24-Hour Turnaround: How Clean Oil Restored Production at a U.S. Paper Mill

By Donaldson Hy-Pro Marketing on Wed, Nov. 05, 2025

Topics: contamination fluid cleanliness ISO Fluid Cleanliness Codes filter elements cleanoil hydraulic oil cleanliness hydraulic oil maintenance lubrication systems

5 min read

Is Your Oil Sample Accurate? Step-by-Step Procedures + Free Checklist

By Donaldson Hy-Pro Marketing on Wed, Sep. 17, 2025

Topics: contamination new oil fluid samples samples cleanoil oil handling best practices hydraulic oil cleanliness

8 min read

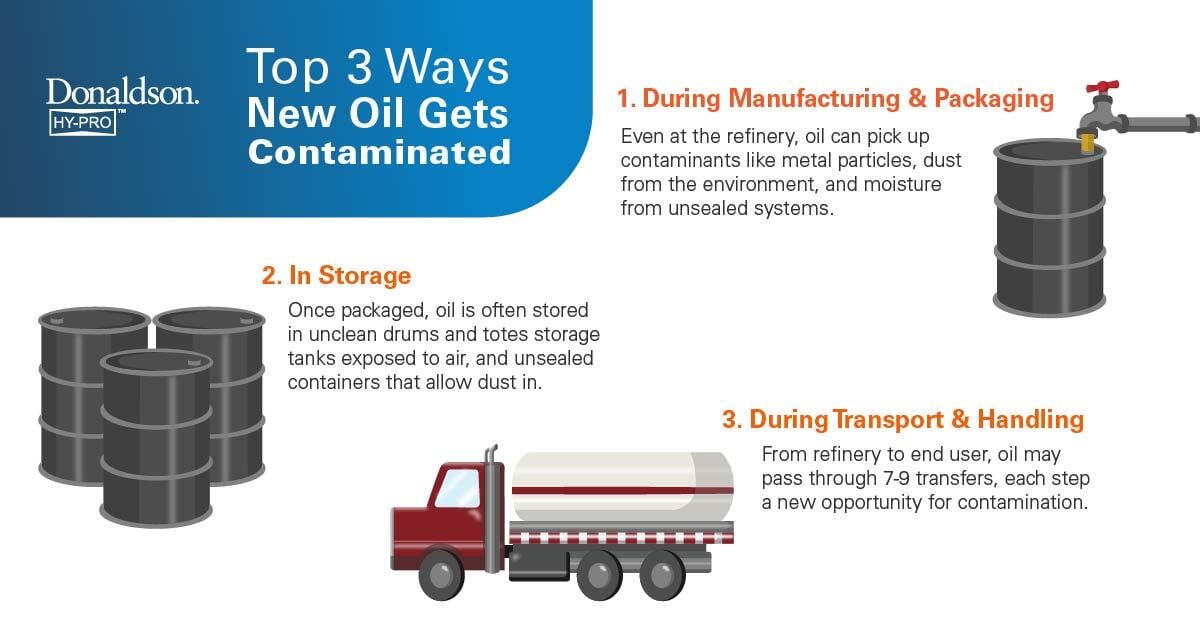

Is New Oil Clean? The Truth About Oil Contamination and How to Handle It

By Scott Howard on Mon, Sep. 08, 2025

Topics: contamination new oil cleanoil oil handling best practices hydraulic oil cleanliness

1 min read

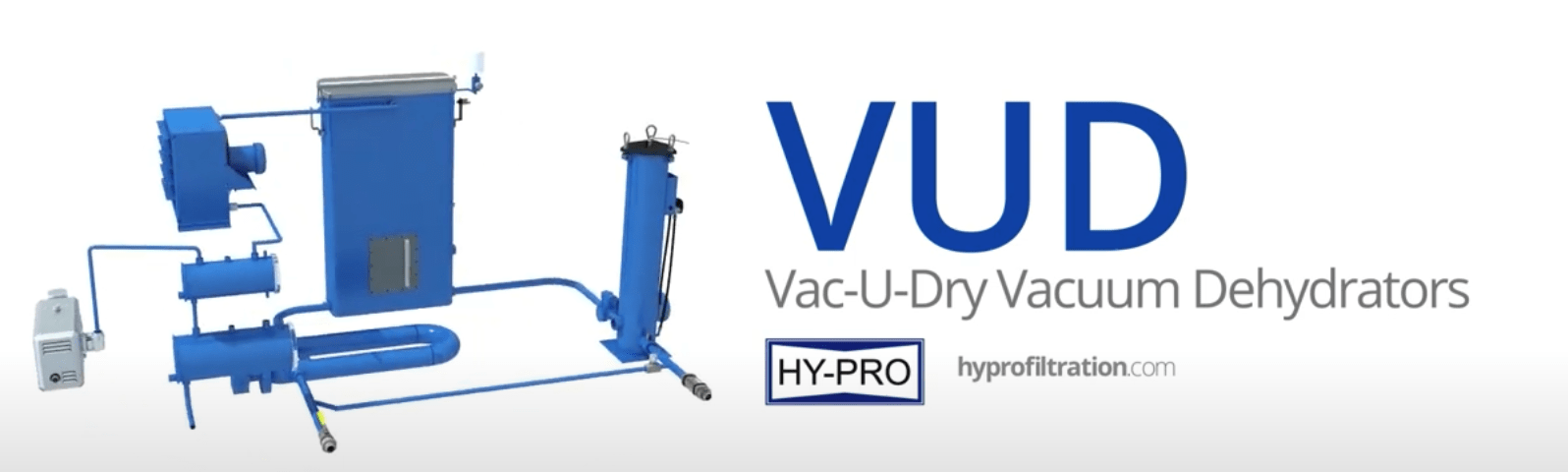

Hy-Pro Vac-U-Dry Vacuum Dehydrator (VUD) Explainer Video

By Hy-Pro Marketing on Tue, Jul. 26, 2022

Contamination is Complicated; Removing it is Easy

Check out our latest product explainer video on Hy-Pro's VUD

The optimized balance between heat, vacuum, process design, and an easy, user-friendly operating system for removal of water and particulate from hydraulic and high viscosity lubricating oils. Equipped with generously sized, high-efficiency filtration, the VUD is the ultimate oil purifier. Keeping fluids clean and dry extends component and bearing life, increases productivity, minimizes downtime, and extends useful fluid life. The VUD is ideal for removing all forms of water, including free, emulsified, and dissolved water and gas from hydraulic and lubricating oils.

Topics: contamination fluid cleanliness vacuum dehydration vacuum dehydrator fluid contamination VUD cutdirtcutcosts hypro

4 min read

Four Ways Outside Contaminants Enter Your System

By Scott Howard on Thu, Apr. 15, 2021

Four Ways Outside Contaminants Enter your System

As an equipment owner or manager, the last thing we want to find in our system is contamination. After all, contamination means loss of efficiency or even downtime, which ultimately costs time and money. Contamination somehow always sneaks its way into our systems. So, how does contamination get in our systems and what are we supposed to do about it?

Topics: contamination oil analysis breathers

1 min read

Hy-Pro's Product Spotlight: Compact Offline Filter (COF)

By Hy-Pro Marketing on Thu, Apr. 01, 2021

Hy-Pro's Compact Offline Filter

Our newest and smallest unit yet, the Compact Offline Filter is able to fit where no other filtration equipment can. Ideal for smaller systems or where a larger offline system wouldn't fit, this solution can be permanently installed or made portable for ease of use.

to fit where no other filtration equipment can. Ideal for smaller systems or where a larger offline system wouldn't fit, this solution can be permanently installed or made portable for ease of use.

Topics: hydraulic fluid contamination dirt Water Contamination hydraulic filters hydraulic and lubrication filter types Gearbox filtration new oil micro-dieseling fluid samples filtration oil analysis hydraulic pump filters hydraulic valve FSL liquid conditioning station duplex low-pressure oxidation Noria NSD hydraulic cellulose media compressor Reliable Plant filter comparison lube oil aluminum refinery conditioning turbine oil glass media

3 min read

Getting to Know Demulsibility

By Hy-Pro Marketing on Thu, Mar. 25, 2021

Demulsibility

What is Demulsibility?

Demulsibility is the ability of oil to separate from water. Oil and water naturally separate because like molecules attract each other. Oil sticks with oil, water sticks with water. Oil is "hydrophobic", or "afraid of water," which is a benefit when it comes to fluids like turbine oil.

Topics: varnish in hydraulic oil varnish in turbine oil contamination water in oil dirt Phosphate Ester diesel engine maintenance steel mills vacuum dehydration rolling mill lubricating oil filter housing sizing micro-dieseling thermal event ISO 4406 vacuum dehydrator fluid samples oil analysis metal analysis paper mill hydraulic pump samples COD duplex low-pressure gearbox contaminination hydraulic duplex high-pressure cellulose media filter elements filter comparison aluminum refinery lab

6 min read

What to Look for in a Dissolved Metal Analysis

By Jennifer Yeadon on Thu, Mar. 08, 2018

Oil can be high maintenance. It’s not something you just dump in your system and forget about. You have to monitor it, manage it and oversee it. Just letting oil cycle through your system without routinely testing it is a sure ticket to equipment damage.

.png)

.png)

.png)