Managing the integrity of the fluids used in critical assets to reduce downtime

The risks related to Precious Metals mining can be quite daunting. Commodity price volatilities, Mineral Resources and Reserves estimates, Remote locations, Austere environments, Accidents, Labor, Environmental impacts are just a few of the many inherent risks mining companies must manage successfully.

Intimately tied into these risks are the formidable investment in the assets needed to mine Precious Metals! These assets are exposed to the harsh elements and contaminants found in the mining environment in which they must operate.

Table1 Identifies the critical assets found in mining operations on which our solutions will have a significant impact in removing contaminations consistently found in precious metals mining operations

Whether you are referencing the Noria Corporation or an oil manufacturer, such as Chevron, it is common knowledge throughout the industrial component manufacturing industry that 70-80% of component failures (found in the majority of your critical assets) are caused by fluid contamination, i.e. Metal Wear-Foreign ingression, Water, Oxidation by-products.

Table 1: Precious Metals Mining Assets Systems and Contaminations

[1] Case Study: Hitachi EX2800 excavator at a mine site: https://info.hyprofiltration.com/hubfs/docs/Case%20Studies/Hitachi%20Excavator%20(Published).pdf?hsCtaTracking=9a7d3724-d199-4957-9626-9d40b85e8ac6%7Cfba6a320-3644-438f-95a7-b736d07e9a2b

In addition, operational costs related to Crushing-Hauling, Power and Maintenance represent respectively 6%, 5% and 19% of the Total Operational yearly costs of a mine[1] which can mount into the tens and hundreds of millions of dollars per site.

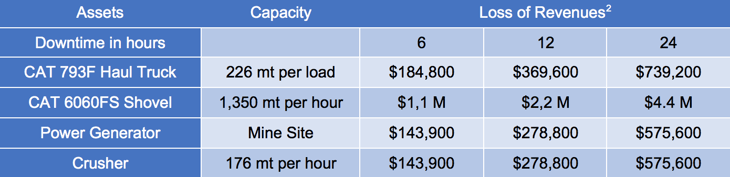

As unsettling as the operational cost are, what is even more disconcerting are the loss of revenues related to the downtime due to breakdowns of key mine site assets. To demonstrate the impact on the potential loss of revenue due to downtime of critical systems/assets, Table 2 presents an example of a remote Canadian gold mine with an average Head Grade of 3.48 g/metric ton and an Overall Recovery rate of 87%.

Table 2: Loss of revenues due to downtime on its critical systems/assets-Gold Mine

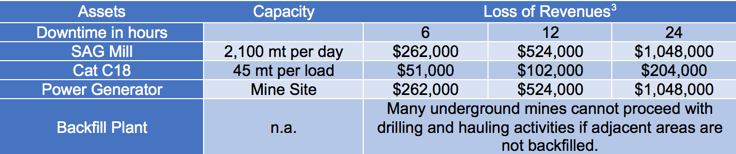

Another example, Table 3 looks at a remote American silver mine with an average Head Grade of 455 g/metric ton and an Overall Recovery rate of 80%. This mine also processes gold, lead, and zinc.

Table 3: Loss of revenues due to downtime on its critical systems/assets-Silver Mine

The Solution

The most honest and precise entities in the world that will never lie to you are, NUMBERS! Numbers don’t lie, they are what they are and provide as we all know DATA. That is what and why we use them at Hy-Pro. One of our mottos is: DATA is key for decision making.

Therefore, we recommend that four (4) important metrics should be added to your mine site’s KPI dashboard:

-

ISO Codes: Metric that evaluates the level of solid contaminations in your hydraulic, lubrification, and diesel fluids

-

PPMs: Metric that evaluates the level of water contaminations in your hydraulic, lubrification, and diesel fluids

-

Acid Number (AN): Metric that evaluates the acidity of your hydraulic and lubrification fluids. Fluid acidity is a precursor to the appearance of oxidation by-products and inevitably varnish.

-

Metal Wear Ratio: Metal Wear count / ISO Code particle count will indicate the ratio of internal wear of key system components (e.g. Pumps, Cylinders, Valves… from SAG Mills, Backfill plant, Power Generator) in order to predict or indicate component failure.

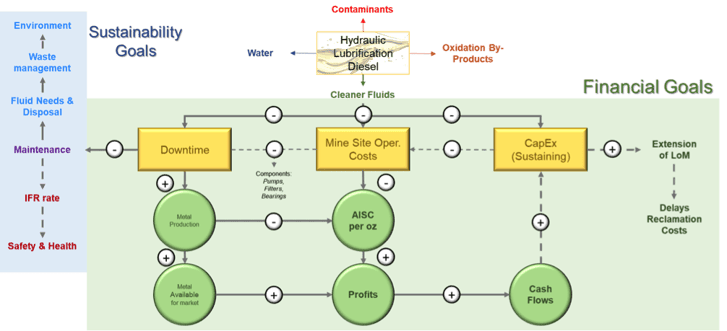

These metrics, based on numbers, will be used to evaluate and track the integrity of the fluids used in your critical assets, as well as anticipate potential costly downtime. Each of these aforementioned metrics will provide you, as well as the key players at your mine site, with information that will guide your team to take actions to positively impact your financial and sustainability goals.

Some questions you might want to ask your reliability team or yourself:

-

What were the last three (3) ISO codes on the SAG Mill? Ball Mill? Crusher? The backfill plant?

-

What are the PPMs in the generator’s diesel fuel?

-

Can I afford to have my crusher down for the next 12 hours?

-

What were the availability ratios for the haul trucks and shovels in the last 24 months?

-

What should be the benchmarks for the ISO Codes, PPMs, AN and Metal Wear Ratio?

-

Can we do better?

These are all questions that we can help you get answers to. At Hy-Pro Filtration, this is what we do daily. By doing what we do very well, we will support you in doing what you do very well.

The Result, Hy-Pro Filtration Solutions Deliver Significant Savings

No matter the site, plant, or industry, by eliminating fluid contamination invariably found in critical systems, due to their operational environment, we at Hy-Pro Filtration have seen and documented significant positive impacts on the operational costs and performances of the plants/sites we have worked with.

Figure 1 Demonstrates the impact we would have on your mine site and Table 4 is a Case Study done on a Metso Norberg MP1000 cone crusher.

Figure 1: How we can impact your financial and sustainability goals

Table 4: Case Study: Metso Norberg MP1000 cone crusher at a mine site in Latin America

[1] Case Study: Hitachi EX2800 excavator at a mine site: https://info.hyprofiltration.com/hubfs/docs/Case%20Studies/Hitachi%20Excavator%20(Published).pdf?hsCtaTracking=9a7d3724-d199-4957-9626-9d40b85e8ac6%7Cfba6a320-3644-438f-95a7-b736d07e9a2b

Learn more!

Visit Hy-Pro Corporation Mining Industry solutions