Guest post today by Dan Helgerson. He is the Technical Editor of the Fluid Power Journal, where this article was originally published.

We have been talking a lot about filtration here at the steel mill. My predecessor had done a remarkable job in educating by example, demonstrating the need for good control of the fluids in our hydraulic and lubrication systems. He had helped stop the leaks and had added well-thought-out filtration systems that have resulted in substantial savings and increased productivity.

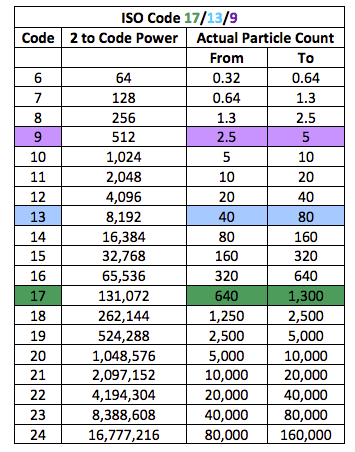

There is still a lot of work to be done and in pursuing that we have invited a number of vendors in, each offering an approach to getting and maintaining an acceptable fluid cleanliness level. The one thing that they all have brought to the table is a discussion of the ISO Cleanliness code. I was in a meeting with a group of managers when one vendor began to talk about the code. Being a Certified Fluid Power Accredited Instructor (AI), I immediately saw this as an obvious teaching moment, so I asked, “Does anyone here want to know what those numbers mean?” The answer was a quick and resounding, “No!”