2 min read

Factory Side Chat Podcast, Episode 9, Reducing the Total Cost of Ownership with a Kidney Loop or Offline Filtration unit

By Hy-Pro Marketing on Fri, Aug. 26, 2022

Topics: fluid cleanliness ISO Fluid Cleanliness Codes cleanliness hydraulic oil Podcast Factoryside Chat Podcast cutdirtcutcosts kidney loop

1 min read

Hy-Pro Vac-U-Dry Vacuum Dehydrator (VUD) Explainer Video

By Hy-Pro Marketing on Tue, Jul. 26, 2022

Contamination is Complicated; Removing it is Easy

Check out our latest product explainer video on Hy-Pro's VUD

The optimized balance between heat, vacuum, process design, and an easy, user-friendly operating system for removal of water and particulate from hydraulic and high viscosity lubricating oils. Equipped with generously sized, high-efficiency filtration, the VUD is the ultimate oil purifier. Keeping fluids clean and dry extends component and bearing life, increases productivity, minimizes downtime, and extends useful fluid life. The VUD is ideal for removing all forms of water, including free, emulsified, and dissolved water and gas from hydraulic and lubricating oils.

Topics: contamination fluid cleanliness vacuum dehydration vacuum dehydrator fluid contamination VUD cutdirtcutcosts hypro

2 min read

Factory Side Chat Podcast, Episode 8, Partners for Life

By Hy-Pro Marketing on Thu, Jun. 02, 2022

Hy-Pro's Factoryside Chat is now available on Apple Podcasts, Spotify, Podbean, and YouTube.

Topics: fluid cleanliness cleanliness hydraulic oil filter elements Podcast Factoryside Chat Podcast cutdirtcutcosts partners for life

4 min read

Official Donaldson Hy-Pro Product Catalog for 2025

By Hy-Pro Marketing on Thu, Apr. 21, 2022

The 2025 Donaldson Hy-Pro Product Catalog for Filter Elements and Filtration Equipment is Now Online!

The newest and updated Hy-Pro Filtration Product Catalog is now available online and easier to use than ever before with interactive elements that are not possible in a printed catalog - always available, simple to browse, and information is easy to share.

Click here to view the 2025 Donaldson Hy-Pro Product Catalog

Topics: Hy-Pro Product Catalog Hy-Pro Product Guide

2 min read

Factory Side Chat Podcast Episode 7 Filter Sizing and Selection

By Hy-Pro Marketing on Sat, Jan. 29, 2022

Hy-Pro's Factoryside Chat is now available on Apple Podcasts, Spotify, Podbean, and YouTube.

Topics: filter housing sizing filters filter sizing filter elements Podcast Factoryside Chat Podcast

2 min read

Expanding the distribution of our Podcast; Apple Podcasts, Spotify, and PodBean

By Hy-Pro Marketing on Tue, Oct. 12, 2021

Hy-Pro's Factoryside Chat is now available on Apple Podcasts, Spotify, and Podbean.

Topics: iso cleanliness codes DFE contaminination Podcast ISO 23369 Factoryside Chat Podcast

8 min read

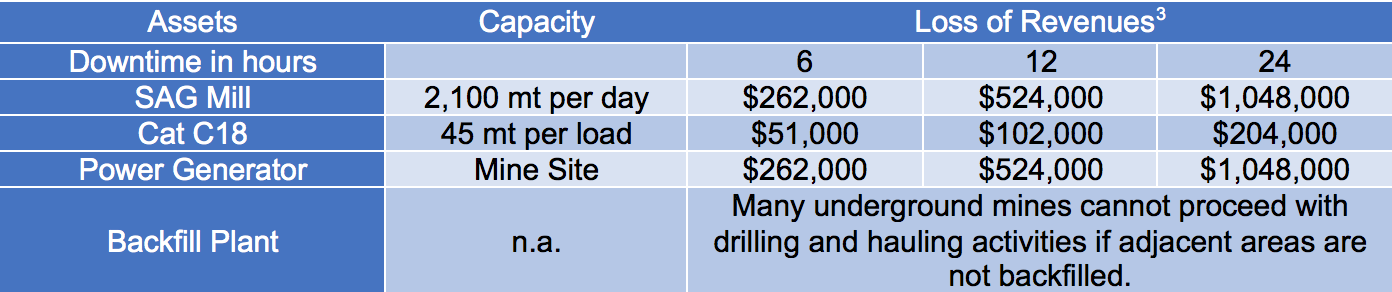

Precious Metals Mining - Managing the Integrity of Fluids to Reduce Downtime

By Daniel Guerin on Thu, Sep. 09, 2021

Managing the integrity of the fluids used in critical assets to reduce downtime

The risks related to Precious Metals mining can be quite daunting. Commodity price volatilities, Mineral Resources and Reserves estimates, Remote locations, Austere environments, Accidents, Labor, Environmental impacts are just a few of the many inherent risks mining companies must manage successfully.

Intimately tied into these risks are the formidable investment in the assets needed to mine Precious Metals! These assets are exposed to the harsh elements and contaminants found in the mining environment in which they must operate.

3 min read

When New Oil Turns Dark

By Hy-Pro Marketing on Thu, May. 13, 2021

When New Oil Turns Dark

Maintenance professionals who have implemented Oil Analysis Programs (OAP) into their Preventative Maintenance Program understand, at some point, it's going to happen, we don't know when, or where, but one day our new oil is going to start to turn...dark.

4 min read

Four Ways Outside Contaminants Enter Your System

By Scott Howard on Thu, Apr. 15, 2021

Four Ways Outside Contaminants Enter your System

As an equipment owner or manager, the last thing we want to find in our system is contamination. After all, contamination means loss of efficiency or even downtime, which ultimately costs time and money. Contamination somehow always sneaks its way into our systems. So, how does contamination get in our systems and what are we supposed to do about it?

Topics: contamination oil analysis breathers

2 min read

The Dollars and Sense of Fluid Cleanliness

By Hy-Pro Marketing on Thu, Apr. 08, 2021

The Dollars and Sense of Fluid Cleanliness

The old phrase will always stand true, "A penny saved is a penny earned." When it comes to businesses and their pennies, every penny counts. When problems during the production and manufacturing process are fixed, people will say "pennies well spent." So, if pennies are so important, then what about dollars? What about thousands, or hundreds of thousands of dollars? What about millions of dollars? In today's production and manufacturing economy, these kinds of numbers are game-changing.