Water, it's a compound that is required for practically everything on the earth. But within a lubrication or hydraulic system, it's one of the most damaging contaminants possible. Unfortunately, it's also one of the most common contaminants you'll find in your system.

When your lubrication or hydraulic system is continuously or even periodically exposed to high water levels, it can result in a mountain of damage. You can find evidence of water contaminant destruction if you look close enough. This damage appears

- Metal etching (corrosion)

- Abrasive wear

in hydraulic components - Dielectric strength loss

- Fluid breakdown

- Additive precipitation and oil oxidation

- Reduction in lubricating properties

What are the sources of water contamination?

As mentioned above, water is one of the most common contaminants, therefore, it finds its way into your oil and equipment in multiple ways. There are many sources of water contamination, including:

- Condensation

- Reservoir leakage

- Worn actuator seals

- Heat exchanger leakage

- New oil

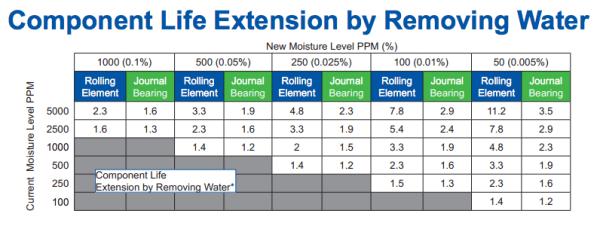

Once water seeps its way into your fluids and equipment, the damage and destruction can result in bearing fatigue, accelerated abrasive wear, corrosion of metal surfaces, increased electrical conductivity, viscosity variance, loss of lubricity and fluid additive breakdown. It's essential to get control of water contamination before it wreaks havoc on your systems.

Hydraulic Oil Water Removal

Fortunately, there is a solution. Removing water from hydraulic oil will extend the life of your components greatly. Hy-Pro offers water contamination solutions, including