Extending Bearing and Component Life and Saving Money

Improving fluid cleanliness means reduced downtime, more reliable equipment, longer fluid life, and fewer maintenance hours. In addition, it also means reduced component replacement and repair expenses.

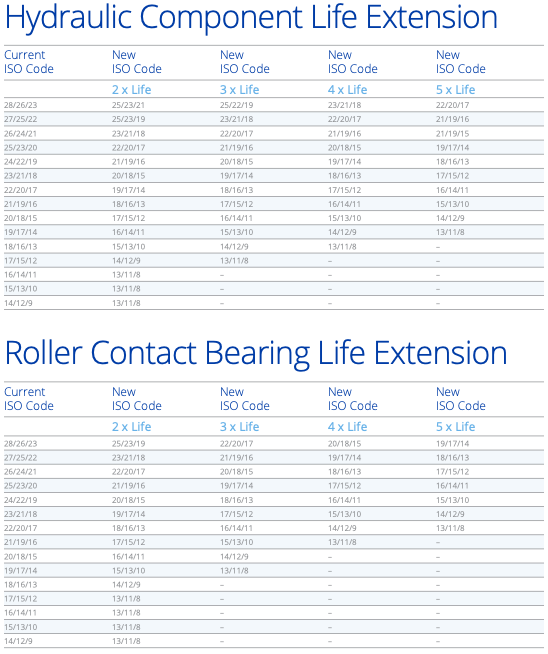

By improving the cleanliness of your fluid by only a few ISO Codes, you can directly increase the lifespan of your components and equipment. The tables below demonstrate the life extension for both roller contact bearings and hydraulic components given a reduction in ISO Codes.

How clean is your new oil?

As it turns out, new oil can be one of the worst sources of particulate and water contamination.

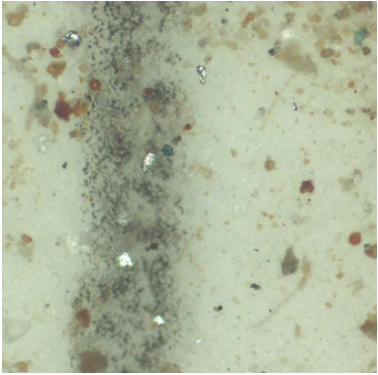

The picture above was taken from a patch test at 10x magnification on a new oil sample direct from the manufacturer and shows the level of contamination present in seemingly clean oil.

The picture above was taken from a patch test at 10x magnification on a new oil sample direct from the manufacturer and shows the level of contamination present in seemingly clean oil.

A good upper limit for new oil cleanliness is 16/14/11. However, a commonly seen ISO Code for new oil reaches an ISO Code of 25/22/19, which is not only not suitable for hydraulic or lubrication systems but can actually be a major cause of degradation and premature component failure.

Hy-Pro will help you develop a plan to achieve and maintain target fluid cleanliness. Arm yourself with the support, training, tools and practices to operate more efficiently, maximized uptime and save money.