Combined Cycle Journal recently published an article on turbine lube oil varnish written by Peter Dufresne Jr. and his team at EPT. We’ve divided the article into four blogs to make it easier to digest -- click here to find parts one, three and four.

Recent posts by Brad Bainbridge

2 min read

Turbine Lube Oil Varnish and Removal Strategies: Part 2 of 4

By Brad Bainbridge on Tue, Jul. 29, 2014

Topics: varnish SVR hydraulic oil contaminination lube oil turbine oil

2 min read

Turbine Lube Oil Varnish and Removal Strategies: Part 1 of 4

By Brad Bainbridge on Tue, Jul. 22, 2014

Topics: varnish SVR hydraulic oil contaminination lube oil turbine oil

3 min read

How to Change Out a Filter Element

By Brad Bainbridge on Wed, Jun. 11, 2014

Changing a filter element can cause massive contamination ingression if the proper precautions are not taken and the proper procedures followed. We have compiled a step-by-step guide to minimize contamination ingression while changing out elements. Check out how to change out a filter element below

Topics: contaminination filter elements

4 min read

Diesel Fuel Filtration 101

By Brad Bainbridge on Wed, Apr. 02, 2014

Reduce unplanned downtime and maximize the fuel efficiency of your diesel engines

Diesel engines are widely used today. You can find them inside buses and tractor trailers traveling our roads, humming along in construction equipment and drill rigs, submerged in marine environments and helping save lives in hospital generators, amongst many other applications. Diesel engines are popular for good reason. Not only do they have cleaner exhaust emissions, they are also known for more reliable starts

Topics: water Water Contamination diesel filtration case study contaminination

1 min read

Unmanaged Phosphate Ester: What Really Happens

By Brad Bainbridge on Mon, Nov. 11, 2013

If you deal with phosphate ester (PE) based hydraulic and lubricating fluids, then you likely understand how important it is it to keep it under control. Millions of dollars and thousands of downtime hours are wasted each year by power plants, military and industrial users who need solutions to properly maintain PE fluids. If they're not managed, major damage can take place to your equipment and to your fluids. Let's take a look at what really happens when phosphate ester is out of control.

Topics: hydraulic fluid Phosphate Ester EHC acid

4 min read

[Video] How Big is a Micron?

By Brad Bainbridge on Mon, Aug. 26, 2013

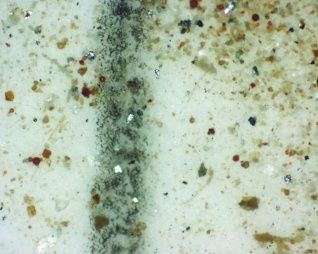

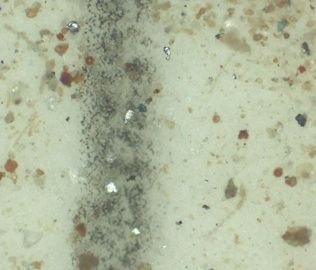

If you’ve been following our blog, you probably have a pretty solid understanding of ISO fluid cleanliness codes (if not, click here). You know that ISO codes quantify levels of particulate contamination at three different micron sizes (4μm/6μm/14μm), but how big is a 4μm particle? Watch the video below for a brief explanation of micron size.

Topics: iso cleanliness codes video

1 min read

Eliminating Filter Element Sparking

By Brad Bainbridge on Mon, Aug. 12, 2013

Static electricity is an amazing thing. It can cause hairs to stand on end when rubbed with a balloon, which can cause it to then stick to a wall. (It’s a fun trick, especially for kids). Unfortunately, when it comes to interaction with filters, static can have devastating results.

Topics: thermal event varnish SVR NSD filter elements

2 min read

Getting Started with Selecting Target ISO Cleanliness Codes

By Brad Bainbridge on Mon, Jul. 29, 2013

Here at Hy-Pro, we understand the importance of selecting target ISO Cleanliness Codes. That’s why we’ve put together this set of instructions for selecting target codes in case you’re in need of a little help.

Topics: iso cleanliness codes

3 min read

How Clean is New Oil? - Part two

By Brad Bainbridge on Mon, Apr. 15, 2013

If you didn’t happen to catch last week’s blog or want to jog your memory, click here.

Last week we discussed how new oil picks up contamination on its way to your facility. This week we’ll continue our investigation of how your new oil isn't really clean. Let's take a look at a three more reasons your new oil continues to be contaminated as it reaches your distributor.

Topics: contamination new oil liquid conditioning station LCS

2 min read

How Clean is New Oil? - Part 1

By Brad Bainbridge on Tue, Apr. 09, 2013

Lubricants and hydraulic oil have to go a long way to make it into your system, which means there's a high potential for it to pick up particulate and water at every step along the way.

Around here at Hy-Pro, we cringe when we think about that process and how our customers put that oil into their machines. We want you to be aware of the state of the oil that you're using, so let's take a look at three reasons why new oil does not mean CLEAN oil.